MASS MIXER WITH LIQUID SPRAYING SYSTEM

We are the prominent and leading manufacturer of Ribbon Blender with liquid spraying system.

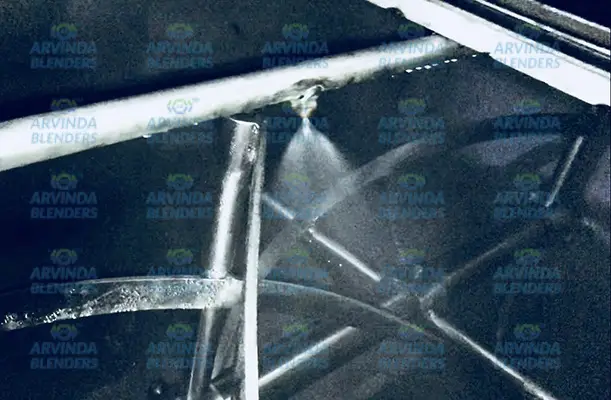

Our versatile and cost-effective Mixing technology with liquid spraying ensures 100% atomization of fine liquid droplets via liquid spraying nozzles. The smaller sizes of the fine liquid droplets are easy gets absorbed by the dry powder particles which are crucial to producing the final product with uniform mixing of liquid over dry solid ingredients.

The flow of the liquid and the parameters of spraying and automation are also conducted by our team so as to maintain the efficiency of the equipment before each new batch.

We also provide the Control panel with many important features for R & D.