WHAT IS NAUTA MIXER OR CONE SCREW MIXER?

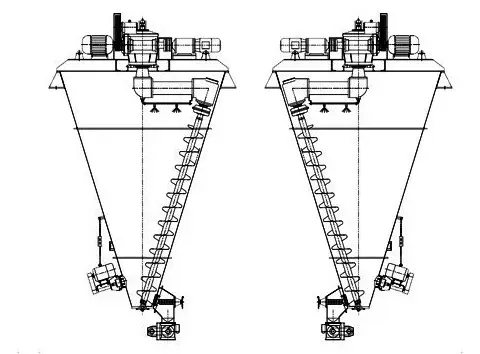

The CONICAL SCREW MIXER OR VERTICAL CONE SCREW MIXER is the most powerful batch type of the mixer specifically suitable for mixing the free-flowing powders, different size granules, mixing dry powder with liquid and mixing the material along with external heating-cooling and drying effect.

The ARVINDA BRAND CONICAL SCREW MIXER or NAUTA MIXER ensures the superior quality of mixing with the highest accuracy and with zero chance of particle size reduction or powder distortion or degradation.

THE WORKING PRINCIPLES OF NAUTA MIXER OR CONICAL SCREW MIXER

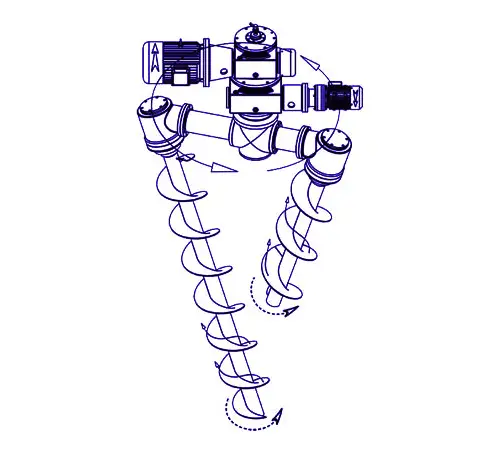

The Nauta Mixer or Conical Screw Mixer consists of the Vertical Cone Shape of the Vessel inside which the screw is mounted upon the central arm. The screw rotates at very High speed around 70 to 80 RPM and rotates at the inside periphery of the Cone Vessel, while the central arm rotates at a very low speed of around 1 to 2 RPM.

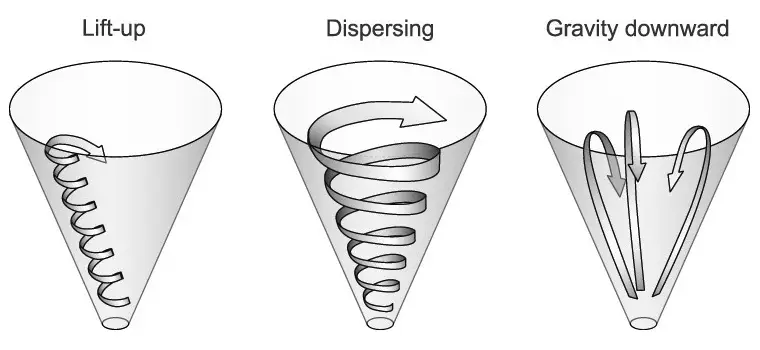

The rotating screw at high speed lifts the raw material from the bottom of the Vessel and conveys it to the upper surface. The Screw rotates at very high speed and which is connected with an extended Central Orbital Arm which also self rotates inside the vessel, which ultimately creates the convective action of mixing of raw materials inside the Cone Shape Mixing Vessel.